Flow Bed Assisted Photopolymerization Manufacturing

A University of Pittsburgh researcher has developed a novel method and system of flow bed assisted photopolymerization based additive manufacturing (FB-PAM). This FB-PAM method is designed to fabricate a variety of composites including ceramics matrix composites (CMCs), polymer matrix composites (PMCs) and metal matrix composites (MMCs) in a cost-effective and high-throughput 3D printing process. This novel approach directly embeds fillers (e.g., fibers or particulates) into any fabricated matrix and could revolutionize the field of 3D printing resulting in low-cost manufacturing of multi material components that currently requires complex fabrication methods.

Description

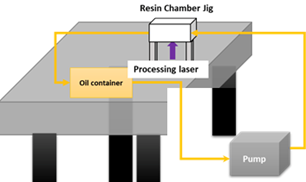

Additive manufacturing (AM) is commonly used to produce structures using layer-wise printing. It can be a cost-effective and timely alternative to fabrication. In photopolymerization based AM (PAM) 3D solids are produced from liquid resins cured following light absorption. However, AM is not suitable in the fabrication of composite material, limiting its industrial application. There exists a great need to develop high throughput AM methods to produce composites in a controlled manner. FB-PAM has the potential to meet this need and can directly embed fillers into a photocurable matrix allowing for the controlled and precise production of multi-material or composite materials using 3D printing techniques.Applications

• Ceramic matrix composites• Polymer matrix composites

• Metal matrix composites