Pressure Sensor with Corrugated Sidewall

Thanks to their biocompatibility and flexibility, microfabricated parylene-based implantable sensors have found a myriad of applications in medical devices. Implantable capacitive micro-pressure sensors are integrated with a miniaturized inductor for wireless pressure reading, making them useful blood pressure monitoring systems. However, geometrical constraints on the formation of a three-dimensional capacitive-cavity chamber, as well as inconsistent diaphragm deflection under a changing applied pressure, make current sensors prone to collapse during fabrication or operation.

Description

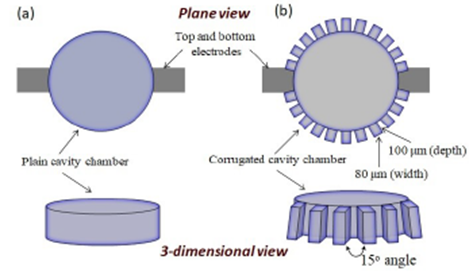

Researchers have developed a novel method of improving the structuring strength and stability of parylene-based microfabricated implantable capacitive sensors. Using a corrugated side wall pattern in place of a straight wall significantly reduces the possibility of membrane collapses during fabrication or operation. Stronger and safer sensors will enable real-time, wireless, implantable blood pressure monitoring systems.Applications

· Implantable, wireless, real-time blood pressure monitorsAdvantages

· Less prone to collapse than previous iterations· Improved functionality of diaphragm deflection

· Pressure sensing range of 200 mmHg is ideal for monitoring blood pressure

Invention Readiness

In vitro dataIP Status

https://patents.google.com/patent/US11504012B2Related Publication(s)

Hur, T.-B., Clark, W. W., Chun, Y., Go, C., Tillman, B., & Cho, S. K. (2019). Improving Structural Strength and Stability of Parylene-Based Capacitive Micro Pressure Sensor Using Corrugated Sidewall. In 2019 IEEE 32nd International Conference on Micro Electro Mechanical Systems (MEMS) (pp. 727–730). 2019 IEEE 32nd International Conference on Micro Electro Mechanical Systems (MEMS). IEEE. https://doi.org/10.1109/memsys.2019.8870736