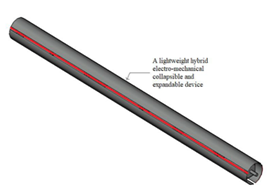

Lightweight Modular Collapsible and Expandable Device

University of Pittsburgh scientists have developed a one-of-a-kind, lightweight modular hybrid electro-mechanical device that forms fiber-reinforced polymer (FRP) segments and sleeves used in guyed structures. This device can be both expandable and collapsable and is produced using glass fiber-reinforced polymer (GFRP). This novel modular construction approach could have a whole host of applications including in the telecommunications and energy sector.

Description

Guyed structures supporting meteorological, communications or broadcast infrastructures are common. With increasing demand for telecommunications services, there is a need to develop more cost-effective, lightweight and dependable building materials. Research has aimed to design and fabricate next-generation FRPs that can not only withstand corrosion from extreme weather but retain the stiffness and strength associated with steel and be maintenance-free. Using GFRP, a prototype guyed tower consisting of segments and sleeves has been designed and produced.Applications

- Telecommunications towers- Meteorological observation structures

- Modular civil engineering construction including wind turbines

Advantages

Currently, the construction of guyed towers uses stainless steel. However, this material can be costly and prone to corrosion due to exposure to extreme weather conditions. With time, towers can become unsightly and need constant maintenance. Developing construction material that does not require maintenance and could withstand extreme weather conditions while retaining structural integrity has the potential to save money across multiple civil engineering projects globally.GFRP is an alternative construction material with a favorable strength-to-weight ratio, is corrosion resistant, low-cost and maintenance-free. Using GFRP, a lightweight modular hybrid electro-mechanical collapsible and expandable device has been developed that can form both uniform and nonuniform cross-section segments, sleeves and associated accessories to fabricate various geometrical shapes. The size of any constructed module can be accurately controlled using threaded rods to allow for the expansion or collapse of modules using either mechanical or electrical motor rotation.

Invention Readiness

A 9 m tower was constructed from 3 identical GFRP segments, of length 2150 mm bonded together to form an equilateral triangle with sides of 500 mm. Testing in laboratory conditions found that a tower with a fiber fraction of 65% deflected less than a steel tower in windy conditions, with a material cost of 30% less. With no maintenance required, long-term cost savings will be even greater. Work is now required to test and validate this approach in larger structures.IP Status

https://patents.google.com/patent/WO2024091665A1Related Publication(s)

Alshurafa, S., Alhayek, H., & Polyzois, D. (2023). Development of GFRP Monopole Guyed Communication Tower. Journal of Composites for Construction, 27(1). https://doi.org/10.1061/jccof2.cceng-3799