Novel Cathodes for Lithium-Sulfur Batteries

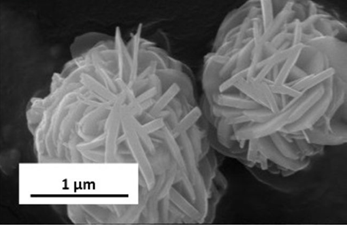

University of Pittsburgh researchers have designed and developed a production method for a novel, scalable, cost-effective, complex framework material (CFM)- based cathode for use in lithium-sulfur batteries (LSBs). Using Super P, an amorphous spherical carbon material, three CFMs were produced. These were functionalized with electronic conductors (ECs), lithium-ion conductors (LICs) and a functional catalyst (FC) (FC-CFM). Together, these CFMs demonstrate very high Li-ion and electronic conductivity for over 100 cycles and could lead to low-cost, novel LSBs being developed.

Description

LSB technology is a potential alternative to lithium-ion batteries (LIB) due to the superior theoretical capacity (1674 mAh/g), specific energy density (2600 Wh/kg), and lower cost of sulfur compared to lithium. Development of LSBs has, to date, been limited by the dissolution of polysulfides (PS) during cycling. Dissolution of PS results in loss of active material from the cathode in LSBs leading to cell failure. This novel approach uses the functionalized CFMs, infiltrated with sulfur (EC-CFM-A and LIC-CFM-S) to trap PS, preventing dissolution. FC-CFM-S can convert PS to pure Li and S preventing sulfur loss. Together these functionalized CFM-based cathodes and dendrite-free Li-anodes could lead to the development of high capacity, scalable and affordable LSBs to meet the growing global demand for Li-based batteries.Applications

• Lithium-ion battery development• Consumer electronics

• Electric vehicles

Advantages

The global supply of lithium is dwindling, but demand for Li-ion batteries is growing. To match this need, alternative batteries including LSB need to be developed. These novel cathodes overcome existing challenges with a Li-S cathode in several ways. CFMs have a high surface area and pore volume and, together with the functionalization by ECs and LICs, produce cathodes that have very high ionic and electronic conductivity along with the ability to bind and trap PS, preventing PS dissolution. FC-CFM-S can form sulfur from the PS to enable high-capacity and lead to stable cycling. The functionalized CFMs can be 3D printed allowing for control of surface area, pore volume, and electrochemical properties through doping of the CFM.Invention Readiness

Cathodes were prepared using a conventional slurry coating method and 3D printing EC-CFM-S, LIC-CFM-S, and FC-CFM-S. Testing demonstrated all sulfur-loaded CFMs could confine PS and had promising areal and specific capacities suggesting these novel CFM-based structures could be suitable cathodes for high energy density LSBs.IP Status

https://patents.google.com/patent/WO2021119582A1Related Publication(s)

Shanthi, P. M., Hanumantha, P. J., Kuruba Ramalinga, Bharat Gattu, Datta, M. K., & Kumta, P. N. (2019). Sulfonic Acid Based Complex Framework Materials (CFM): Nanostructured Polysulfide Immobilization Systems for Rechargeable Lithium–Sulfur Battery. Journal of the Electrochemical Society, 166(10), A1827–A1835. https://doi.org/10.1149/2.0251910jes